Precision machining, bar turning and assembly: French expertise available internationally

BENOIT JOLIVET: smart solutions for your precision machining requirements around the world

Since 1929, BENOIT JOLIVET has been designing high-precision parts with diameters of 4-50mm made from all types of metal and alloy in a wide range of quantities, from pre-series to medium and mass production runs; our expertise is recognised all over the world.

We’re proficient in three key areas of expertise: bar turning, machining and the assembly of sub-assemblies, ensuring our customers benefit rom

- agile, bespoke solutions

- superior quality parts

- full conformity with even the most stringent standards

- fast, multifaceted service.

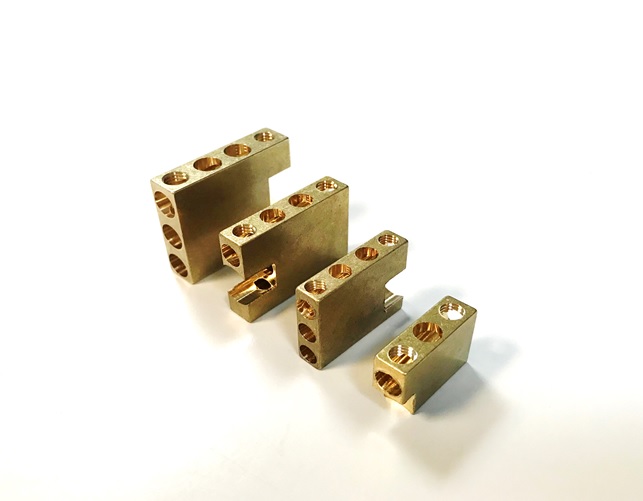

Electrical fittings

Automotive

Equipment

Household Appliances

Hydraulics

Rail Industry

Machine tools and robotics

Sports and leisure

Precision bar turning

Assembly

Your precision machining requirements, spur our innovation

A leading French industrial partner for discerning industry players worldwide

With 95 years of expertise and recognised agility, BENOIT JOLIVET rises to all the challenges of precision machining and bar turning, delivering reliable, effective solutions that focus on quality and adaptability, meeting your needs whatever they are.

Our long-term partnerships with leading carmakers and sports and equipment manufacturers illustrate just how responsive we are, providing effective solutions to meet the most demanding specifications. We can quickly adapt to new developments; we’re also proactive, anticipating changes in technology and innovations in international markets.

Automotive

Sports

Equipment

BENOIT JOLIVET’s proactive approach

BENOIT JOLIVET stands out for its agility; we provide fast, accurate responses in line with the requirements of our customers across the world – and as needed when changes or adjustments are made. The ability to adapt is at the heart of our production process.

- Consultancy and co-engineering: we work closely with our customers to gain a better understanding of the subtleties and particular constraints of their international projects and deliver the best possible technical solutions. We take the initiative, suggesting improvements right from the initial design stages.

- Innovative proposals: we make suggestions and technical recommendations to optimise your part manufacture and performance. Our team is constantly coming up with innovations to improve your products and meet international market expectations.

- Making technical and economic sense: constantly seeking the best balance between advanced technical solutions and economic considerations. We get ahead of challenges to put forward long-term, cost-effective solutions without skimping on quality.

- Personal support: ongoing assistance throughout the life cycle of your products to deliver optimum production efficiency and value. Our proactive approach ensures stringent oversight and real-time adjustments.

- Flexibility: adapting our manufacturing processes to your product life cycle, ensuring solutions are effective and adaptable. We anticipate future needs and adjust our production methods accordingly.

People at the heart of our international success

Our success draws on our human capital in France: our company is characterised by knowledge-sharing as our people, our customers and our suppliers work closely together. This collaborative ethos is what enables us to stay agile, reliable, and at the cutting edge of innovation on international markets.

Your project is our mission: precision machining your parts

Whether you are at the beginning of a new project or planning large-scale production, our team is ready to support you with techno-economic solutions tailored to international markets. Contact us to discover how our expertise in bar turning and precision machining can help achieve your goals.

Technical and economic solution

Quality commitment

Fast delivery times for international orders

Flexibility and agility

Versatility, optimisation, and innovation